Which surgical instruments do you repair?

Replacement of handles of chisels, raspatories, and mallets etc. Insulation of tweezers, etc.

What is adjustment?

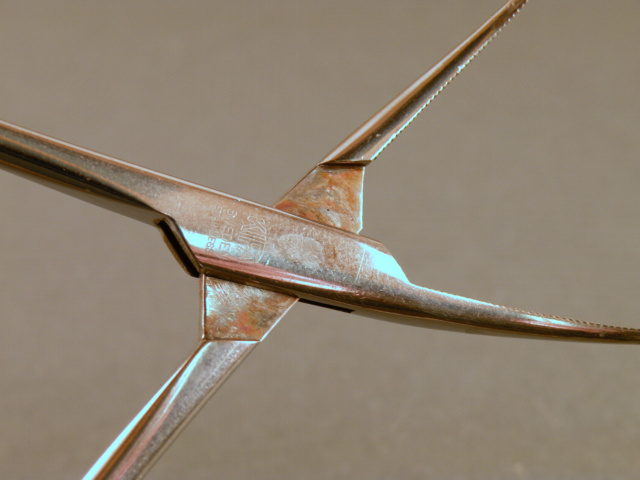

Any instrument consisting of two parts, e.g. scissors, artery forceps, pliers, etc. must be adjusted in order to obtain the best result. Adjusting an instrument means to strike out irregularities with the aid of a hammer, and so the instrument is adjusted back to its standard configuration. Without an adjustment, most of the instruments would continue to perform poorly.

How many times can you sharpen a pair of scissors?

In general, a pair of scissors is capable of being sharpened at least ten times depending on brand and size. Firstly, the scissors are disassembled and cleaned and later put together and adjusted. Lastly, the scissors are sharpened. Adjusting the scissors beforehand often means that minimal sharpening is needed, which gives the scissors a smooth and perfect cut. The main reason that a pair of scissors looses its quality is because itís been sharpened too much, which will result in a decreased ability to cut.

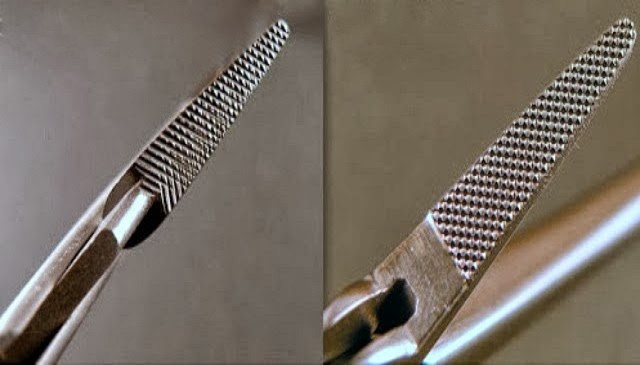

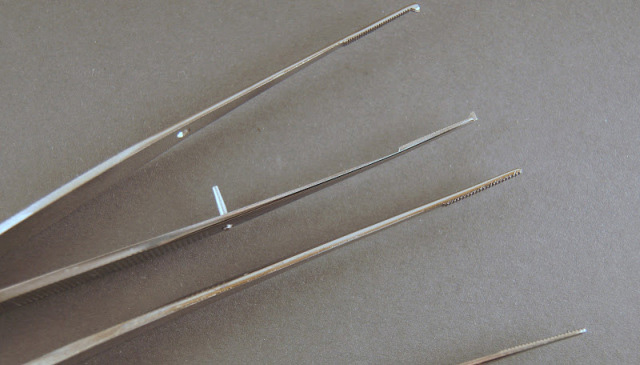

What is serration?

It is a cross pattern most often occurring on needle holders and flat pliers. A needle holder/plier without metal inserts is always serrated, and those surfaces are not as good as hard metal inserts when it comes to the function. This is most noticeable when thin and fragile materials are used.

Do you reinsulate forceps?

Yes, but we do not do it ourselves as another company is taking care of that part. Sometimes you may wonder why it takes a great deal of time to receive your diathermy forceps, and the reason for this is because we are waiting to gather a certain amount of these forceps, because if we did not, the unit price would be very high.

What would you do if the teeth is broken in a pair of forceps/artery forceps?

The teeth in the front of the forceps is used to grip and hold on to different tissues. If the teeth is broken, it is unnecessary to discard a functional instrument. Therefore, we always redo the instrument so it becomes anatomical, which means that the instrument is repaired as usual, except that the teeth is removed. The instrument will be able to be used in other surgical procedures. We will make a note of this on the delivery note.

What is a crack?

A crack is a rupture in the steel of an instrument. Sometimes, it can be difficult to notice, especially if the instrument is discolored or if the rupture has just begun. The easiest way of detecting it is by looking through a loup or a magnifier under strong lightning. Most often it occurs in joints, jaws or near screws on instruments consisting of two parts, e.g. artery forceps, needle holders, pliers etc. where constant strain occurs. Surgical instruments consisting of hard materials, such as chisels, osteotomes and raspatories do seldom have ruptures. Most of the cracks that are discovered occur on old instruments, but also on new ones, where the cause usually is because the instruments are consisting of stainless steel of poor quality. A crack does not only imply a risk for the instrument to break, it also deteriorates the stability and the function of the instrument significantly. Cracks can not be repaired.

What does Sundtorp Innovationís quality assurance mean?

At the arrival of the instruments, most of the errors existing are detected. These errors can be cracks or that the instruments are worn out for various reasons. The instruments are constantly controlled during the different stages of repairment; adjustment, sharpening and polishing. The last control check occurs when cleaning/lubricating the instruments. Instruments that are not repairable are marked in red. The rest of the instruments that are sent back are guaranteed to not have any visible cracks and are ready to be used again in different surgical procedures. The quality assurance is completed.

What are the advantages of high-polished instruments?

Rust, corrosion and other coatings/discolorations will disappear. Cracks are detected, even the most difficult ones. A polished surface makes it difficult for corrosion to take place. It becomes easier to clean the instruments, and irregularities on the surface disappears. The quality of the instrument is improved significantly.

Is it possible to polish your surgical instruments on your own?

There are a number of various polishing liquids on the market, but non that we recommend to surgical instruments, since it can have the opposite effect in some cases. Strong detergents containing abrasive paste can be corrosive and discoloration may occur. If you succeed with polishing your instruments, it is almost impossible to clean an instrument consisting of two parts, e.g. forceps etc. around screws and joints etc, which are the places where rust and discoloration occur the most.

We suggest that no polishing detergent should be used for surgical instruments. We also recommend not to use corroded instruments in surgical procedures because the risk of the instrument breaking increases. These instruments should immediately be sent for reparation.

We suggest that no polishing detergent should be used for surgical instruments. We also recommend not to use corroded instruments in surgical procedures because the risk of the instrument breaking increases. These instruments should immediately be sent for reparation.

Are all surgical instruments stainless?

Not all instruments are completely stainless, as all instruments withstand rust differently. We recommend that you require good quality of your instruments. One cannot know for sure for how long an instrument will be free from rust, since it depends on how the instruments are taken care of. When newly purchased instruments are beginning to get discolored or corroded after being washed several times, then it might indicate that the instruments have poor quality. If this is the case, contact the manufacturer. It can also indicate that somethings wrong in your washing-process, and it needs to be checked immediately.

Why good quality?

Instruments with poor quality do not only rust/get discolored faster, the steel is also often significantly softer. This means that the instruments are bent more easily and cannot withstand strains. Instrument that need to be sharp (e.g. scissors, pliers, chisels etc.) are becoming blunt faster. These instruments do not only require service more frequently, but are also lasting shorter time compared to other qualitative instruments. A good quality instrument should last at least ten years.

Does the label of the etching remain after reparation of an instrument?

No. Sharpening, blasting and polishing are needed in order for the instruments to regain their original surface. It does not only increase the quality of the instruments, but it also provides safety due to that no sharp surfaces or damages are left on the instruments that possibly could unravel surgical gloves or harm the surgeons involved.

Is it possible to retain the label on the instrument after reparation?

To some extent. In order to repair an instrument, certain stages are required that may remove the label. It is difficult to retain the label on all types of instruments, but if you wish to retain the label we will attempt to leave the label unchanged if possible. Please note this on the delivery note.

Does Sundtorp Innovation have the possibility of relabeling your instruments?

Yes. We can etch different types of instruments according to your requirements. Please contact us if you wish to relabel your instruments.

NOTE!

Some instruments are made of other material than stainless steel, such as uterine sounds, muscle biopsy cannulas, probes, scalpel handles etc. These instruments are covered in a steel alloy, which eventually wears off. When this happens, these instruments need to be separated from instruments made of stainless steel, otherwise corrosion will occur. Note that corrosion only take place in a moist environment. Please contact us for more information.